Peel Testercompany|peel testing software : ODM 180°-peel. The 180-degree peel test quantifies the force required to peel apart bonded materials at a right angle to the bond. It can be used to examine the binding between a flexible material and a hard substrate. 90°-peel . The 90 . webGet the 2024 season Argentine Primera C standings on ESPN. Find the full standings with win, loss and draw record for each team.

{plog:ftitle_list}

WEBRecently, security researcher Jeremiah Fowler discovered and reported to sitePlanet about two non-password protected databases containing over 18 million records. Upon .

Peel testing expertise for adhesives, coatings and laminates allowing accurate measurement of peel strength, coating durability and adhesive performance.180°-peel. The 180-degree peel test quantifies the force required to peel apart bonded materials at a right angle to the bond. It can be used to examine the binding between a flexible material and a hard substrate. 90°-peel . The 90 .A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, .

The S-PRT-2500 is used to perform the peel strength test. More specifically, it tests the bond between the adhesive/PE (or PP) top coat layers and the FBE layer. Advantages: Completely wireless connections Highly compatible and .

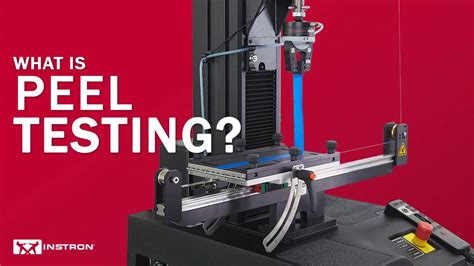

what is peel testing

Our digital peel testers are supplied with a dedicated library of pre-programmed peel test setups and advanced analysis software displaying test results as graphs. By adding the proper set of fixtures that matches the shape and size of your sample, our peel testing machines can go from measuring small samples to large samples.Peel tests are performed on universal testing machines that consists of a test frame that is equipped with a load cell, testing software, and application-specific grips and accessories. Many peel tests require the use of a specialized test fixture that maintains the specified peel angle throughout the test. 180° and T-peel testing require only tensile grips.Peel Strength: While not directly measured, peel strength is a key metric calculated from the peel force and the width of the sample. It is usually expressed in N/mm or N/m. The average peel strength across the test can provide a single number to compare different samples or materials, but it’s also useful to look at how the peel strength .Configure your peel testing systems from a wide range of test frames, force sensors, grips, and accessories. See the list of items below for details. Shown at left: F305-IMT test frame with an FS05-20 force sensor and G1008 film and paper grips. Mark-10 .

Peel test is a simple mechanical test to measure the adhesion strength, especially for the case of a thin film deposited on a substrate. Many experimental efforts and analyses have been devoted since the pioneer work of Strong in 1935, and a comprehensive survey on the earlier developments of the subject can be found in Kim and Aravas (1988).The subject will be .This advanced Peel Tester for Adhesives is designed and engineered in accordance with international test standards including: ASTM D3330 (Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape) ISO 8510-2:2006 (Adhesives — Peel test for a flexible-bonded-to-rigid test specimen assembly — Part 2: 180 degree peel)

The phase angles must be known in order to assess and perform a peel test, and the adhesive strength varies with peeling angle. Methods of testing range from the following. Single-coated, peel at a 180-degree angle. (Single-coated film) Peeled at a right angle to the surface. Evaluation of bond flexibility by T-peel testPeel strength is the average load per unit width of the bond line required to separate the bonded material where the angle of separation is 180°. A peel test is performed between two substrates bonded with an adhesive. The substrate can be both flexible or one can be flexible while the other can be rigid. Adhesive usually takes the form of a .

In short, correctly measuring, setting up, recording, and then analyzing carrier tape peel back force is a critical production step. That’s why you need GPD’s Peel Back Force Tester (PBFT) with FORCEWare™ software. This is the equipment judged so good it was used to set the peel back force standard for the entire industry.The APT 100 is a peel tester for measuring the tensile strength of the seals made on various packaging material, including medical bags. The APT 100 is designed to perform peel tests following the ASTM F88/F88M as well as the EN868-5. The machine clamps a specimen and pulls the seal apart, measuring the tensile strength with load cell.

Peel Testing Machine; 1) Load Frame Testing machine load frames can come in single or dual column configurations depending on their force capacity.: 2) Load Cell The load cell is a transducer that measures the force applied to the test specimen. Instron load cells are accurate down to 1/1000 of load cell capacity. 3) Tensile Grip Most peel tests require at least one .Measuring peel adhesion strength is necessary in determining which adhesion is best suited for its desired end use application. ATS and ASTM Peel Adhesion Testing. Since 1967, ATS has delivered testing, inspection, and engineering consulting services of unmatched quality. During the 50+ years since our founding, we have expanded our client base .The M10 Peel Force Tester can be operated without the need for tools, which makes it easy to insert cells and change the peeling angle. M10 HMI is used for operations. All input is done via a touchscreen. Measurement curves can be .

Peel Testing Machine; 1) Load Frame Testing machine load frames can come in single or dual column configurations depending on their force capacity.: 2) Load Cell The load cell is a transducer that measures the force applied to the test specimen. Instron load cells are accurate down to 1/1000 of load cell capacity. 3) Tensile Grip Most peel tests require at least one .

In short, correctly measuring, setting up, recording, and then analyzing carrier tape peel back force is a critical production step. That’s why you need GPD’s Peel Back Force Tester (PBFT) with FORCEWare™ software. This is the equipment judged so good it was used to set the peel back force standard for the entire industry.According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure .Our Peel Tester offers exceptional quality and style within the Test Machine category.Sourcing test machines from China offers competitive pricing, a wide range of product selections, and access to advanced technology. China is known for its manufacturing expertise, and suppliers offer customization options to meet specific requirements .

An alternative to the Climbing Drum Peel when testing the adhesive peel strength between two adhesively bonded solid sheets, the Roller Drum Peel test method dictates a significantly smaller specimen and a smaller fixture. However, since the angle of peel is greater, the Roller Drum Peel test is a more severe test than the Climbing Drum Peel .The 90 degree peel fixture is designed with zero friction so that all force measurements are a direct outcome of the film and adhesive under test. Furthermore, Instron offers a variable angle peel fixture for testing PV modules at angles other than 90 degrees, such as 45 degree or 30 degree peel testing.Peel strength is the average load per unit width of bond line required to separate bonded materials where the angle of separation is 180 degrees. Learn more about 180 degree peel testing in the application note 180 Degree Peel Test on Syringe Blister Pack. Typical graph showing a peel strength test:FP-2260 Friction/Peel Tester: The FP-2260 tester conducts T-peel, 90-degree and 180-degree peel tests on packaging, adhesive, paperboard, label, paper and film materials. The results identify the peel properties. Up to 128 instances of peel test results data can be stored in the system for later review. The load cells are interchangeable.

The graph shows an adhesive tape's typical peel strength curve depending on peel angles. At a peel angle of 30º, the peel strength has its highest value, decreasing gradually with higher peel angles up to a peel angle of about 120º. Here can be seen a turning point, from which the peel strength slightly increases gradually with higher peel .

Preliminary Pages 6 M10-14197-EN Hazard - Set the appropriate limits before performing loop tuning or running waveforms or tests. Operational limits are included within your testing system to suspend motion or

P45-50N 45° Peel Table – Maintains 45 degree peel position; The 45 Degree Peel Tester is an integrated test system. Perform quick and efficient peel tests with the 45° peel fixture, small chucks, motorized test stand, and digital force gauge. The peel fixture holds and peels back container seals and tapes from food and medical packaging, etc.

hach titralab kf1000 series volumetric karl fischer titrator 3 980 distribution

hanna instruments hi 903 karl fischer volumetric titrator distribution

peel testing system

peel testing software

WEBA to C [New] - Google Drive. File size. #1 Anagrams (NSP) (eShop).rar. #1 Anagrams Sudokus Bundle (NSP) (eShop).rar. #1 Crosswords Sudokus Bundle (NSP) (eShop).rar. .

Peel Testercompany|peel testing software